THE COST OF WAITING

- Teslights

- Jul 28, 2017

- 2 min read

Question: What is the cost of Waiting for not replacing Fluorescent tube to high efficiency LED equivalent?

Lighting consumes about 20% energy of any commercial building. We spend 80% of our time indoor. For places like Hospital or even 24 by 7 convenience stores, the lights are always on. For 7-eleven convenience store, assuming there are 50 fluorescent tubes per store operating 24 x 7 at $0.2981 per kWh, the estimated annual bill is $104.45 per tube or $5222.50 per store per year. For a hospital with 5000 tubes, this amount can be $522,250 annually. This is paid to the utility company.

There is probably a maintenance crew to maintain and replace faulty lamps and ballasts. Fluorescent tubes generate heat; thus, the air-conditioning needs to compensate by running harder.

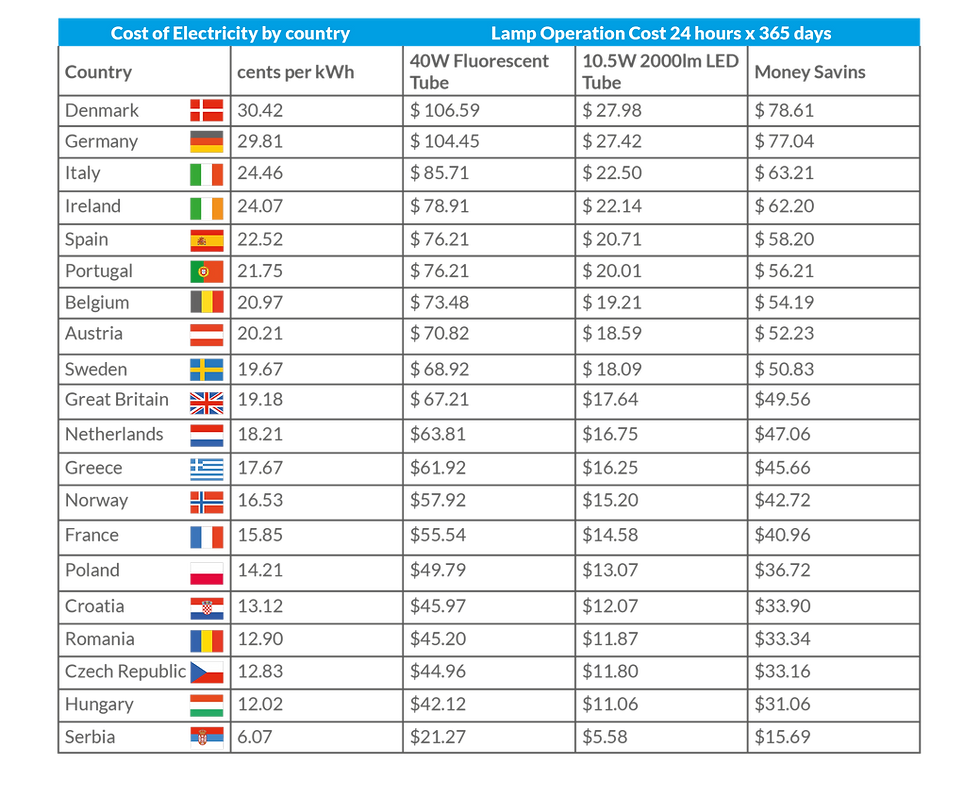

TABLE:The cost of operating the lamp annually (24 hours x 365 days)

Table shows the comparison costs to operate an equivalent LED tube by country with different energy rates. In the case of Germany, the estimated savings per tube per year is $77.04. If the initial purchase price of the tube is $25; the payback is 3 months. The net savings including the initial cost of the lamp for the first year is $52 or $260,200 for 5000 tubes. The LED tube can last say 35,000 hours. This translates to $1.42 M for the life of the lamps.

The Cost of Waiting

Assuming the fluorescent tubes and ballast are free at zero cost. Every year, the cost of operation is $104.45 x 5000 = $522,250. The initial capital outlay to purchase the LED is $125,000. The cost of operating the LED lamps is $137, 100.

Therefore, the cost of waiting is:

$522,250-$125,000-$137,100= $260,150 or $52 per tube

Decision Matrix:

If Do Nothing: The cost of operation is $522,250 for 5000 tubes per year.

If Replace: Need $125,000 capital but Operating Expense saving is $385,150 per year.

If Replace: Payback is 4 months. Positive cash flow on Month 1.

Main Risk: Selecting the WRONG LED tube.

Results

Positive cash flow on Month 1. 70% savings of lighting utility bill. This translates to > 10% of the overall bill.

If tube is part of Operating Expenses, there is positive cash flow in Month 4

If the payment terms is 6 months, the risk of replacement is ZERO risk.

The biggest risk is probably selecting the light that will not decay over time. So, be aware of the low cost LED tubes. A cold to touch tube at above 15W watts means that heat is trapped inside. This is bad for the LED components. See effects in previous Not all Tubes are the same blog.

The cost of making the wrong selection will be high due to hassle to replace. For Hospital, be aware of the Third Harmonic Distortion criteria. 3rd harmonics propagate via the power line and may affect other appliance performances.

Other Intangible benefits are:

Disposal fee to dispose Fluorescent tubes due to Mercury inside tube.

Lower Labor overheads to maintain and replace the tube and ballast

Lower air-conditioning bills

Higher Building Valuation with conversion

Each kWh saved translates to 0.53 kg of CO2E (Carbon dioxide equivalent) reduction. A green hospital.

What are the other potential risks? I seek your comments.

Comments